Context

Due to the continuous development in PCB technology, we have to be innovative and keep ourself updated to the critical requirement. One of our customer has a high reputation in manufacturing designs with special process and most of their manufactured boards falling in to this category.

Solution

It is very important to provide quality output to the customers with an output which makes them feel confident on us to have a trustworthy relationship. To make this possible, skillful and dedication level of our engineers are the most important aspects. We have trained our engineers in such a way that they understand the special process instead of following the routine procedures which themselves to take correct decisions at critical situations.

Process

Every engineer in a team will be allotted to work on the special process on a rotation basis. We have this system to make sure that everyone is able to handle all types of jobs. Also, quality check will be done for all special process jobs which ensures good output. Weekly meetings will be conducted for the engineers by their respective team leaders to clarify their doubts with special processes. Apart from this we have a good process flow which is being done by creating a special checklist for our customers. Our customers library and checklist will be regularly updated as soon as we receive a feedback or an update from them.

Results

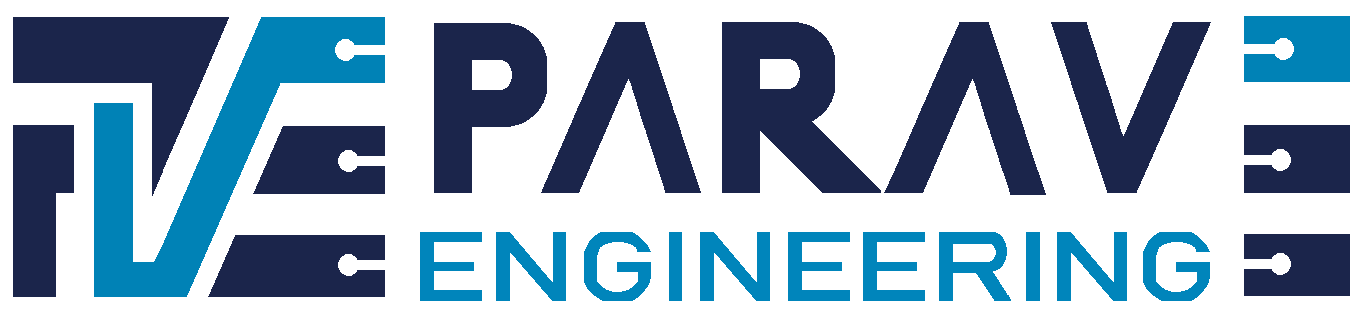

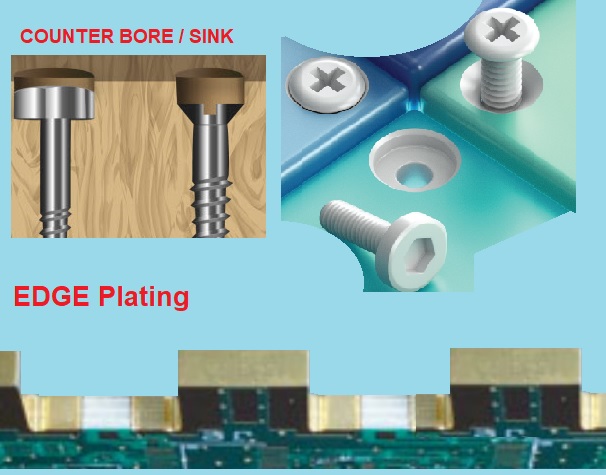

With the very good internal process, we are able to meet the requirements of special process jobs which makes ourself a trusted resource for our customers.Recently we received a very complex design with special processes like blind, buried, stacked laser, cavity and plated edges from the customer. When the completed job was sent back to the customer, they were so happy with the quality of our CAM work on this job and started sending such jobs regularly.